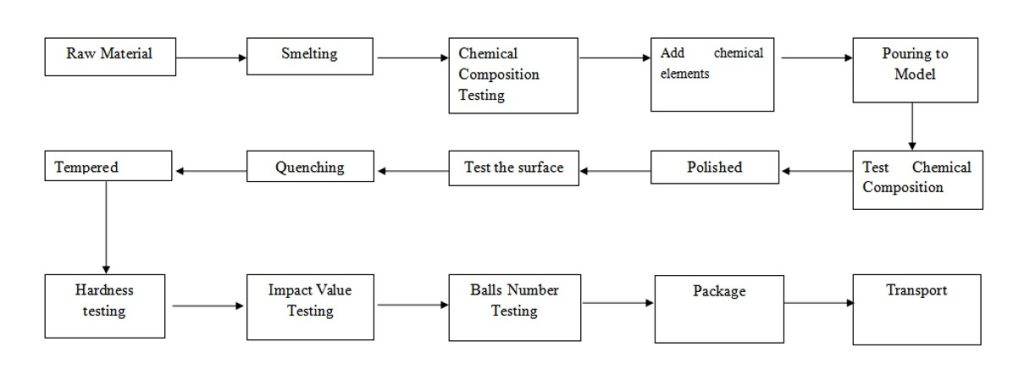

All of our grinding balls are produced and manufactured by our company's independently developed grinding steel ball automatic production lines and equipment. On the one hand, our grinding steel balls have stable performance and are used effectively in mining, cement plants, thermal power plants, magnetic materials and other fields, which truly increase throughput capacity and reduces various costs for customers. On the other hand, it also reflects that our independently developed automatic production linse and equipment are mature in technology and advanced in process.

Our company strictly selects raw material suppliers and select the highest quality raw materials, high carbon ferrochromium and scrap steel as the main raw materials for grinding steel balls. At the same time, in order to improve product quality, we added a rare element to the trace elements of the grinding steel balls. The breakage rate and out-of-roundness rate of the products are significantly better than similar high-chromium steel balls.

cast grinding balls diameter from 8mm to 150mm; forged balls diameter from 20mm to 200mm.

Our company has equipped with four Rockwell hardness testers, which are specially used to measure the hardness of products. At the same time, in order to ensure that the hardness of the surface and core of the grinding steel ball remains balanced, each batch of our products will use wire cutting technology to cut the steel ball profile and measure the internal hardness of the cast steel ball.

The hardness of all our products is greater than 58HRC, and the difference between the surface and core hardness is less than 1HRC. Higher hardness is important for grinding ore without crushing. Therefore, it is very important to control the hardness of the product. The product hardness cannot be too high or too low. It is necessary to ensure that it is within a very scientific and reasonable range in order to achieve the best use effect of the product.

Grinding steel balls are widely used to grind various ores, such as iron ore, copper ore, lead-zinc ore, bauxite, gold ore, limestone, coal or magnetic materials, etc.

There are many selection criteria for how to choose suitable grinding steel balls.

First, according to the size of the customer's specific ball mill and SAG mill and the conditions of grinding ore, choose cast steel balls or forged balls.

Second, choose the right supplier. Manufacturers need to have at least two automated production lines to ensure normal and stable supply. At the same time, we have complete testing equipment to ensure the stability of product quality. At the same time, the customer's price has a certain competitive advantage, thereby reducing procurement costs.

Grinding media are widely used in non-ferrous metal mines, cement plants, thermal power plants, magnetic materials, new building materials and other fields. As grinding media in mills of various ore dressing plants, they are used to re-crush and re-grind ores and materials to achieve ideal fineness. Our company will recommend the use of more matching chemical composition content and physical performance indicators according to the use field of grinding media to achieve more ideal output and efficiency.

We assured you that your personal information will be kept confidential. The personal data we collect is only used to process your inquiry.