We will recommend the best SAG mill grinding ball solution based on comprehensive factors such as the specifications of the SAG mill, the nature of the ore being processed, and the working environment of the mill. By considering these factors, we ensure that our SAG mill grinding balls and SAG mill grinding media provide optimal performance and efficiency.

How to improve the processing capacity of SAG mill is a problem that customers often need to face and solve.

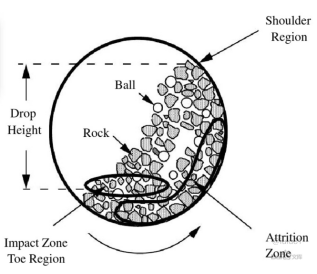

The processing capacity of the SAG mill is usually expressed by the weight of the raw ore processed by the SAG system per unit of time. Factors that affect the processing capacity of the SAG system include the specifications of the mill, the nature of the ore, the operating conditions, and the performance of the sag mill grinding media.

The SAG grinding steel balls of our company are used very well in large SAG mills at home and abroad. The 11-meter SAG mill in Mirador Copper Mine, Ecuador, has never had any quality problems for many years using our grinding balls. The mill operates normally and the processing capacity fully meets the design requirements of customers. Cast balls or forged balls have never had any unexpected breakage, loss of roundness, deformation, etc. during use. Low ball consumption and stable use are the main reasons why customers have always chosen us.

We assured you that your personal information will be kept confidential. The personal data we collect is only used to process your inquiry.