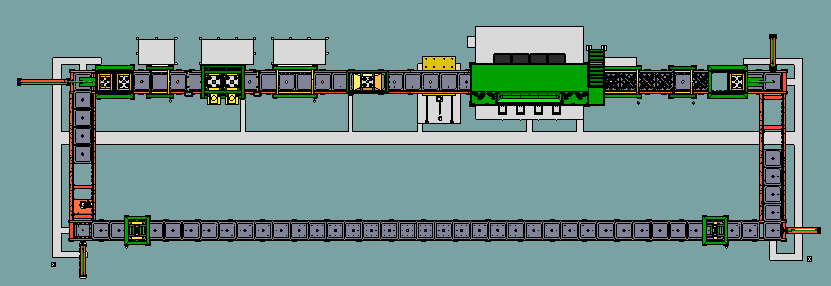

GXLS-840-75 ball casting production line is the fifth generation automatic ball casting production line independently developed by our company. It can meet the annual production demand of 10,000 tons. This production line with mold for cast iron is suitable for the production of various specifications of steel balls from φ40 to 130mm. It has the functions of high degree of automation, easy operation, energy saving and power saving.

1.1 Maximum dimensions: 40m long, 13m wide (specific dimensions can also be designed according to the purchaser's workshop).

1.2 Action mode: hydraulic drive, mechanical drive and pneumatic.

1.3 Control mode: PLC automatic control system for the entire grinding ball production line.

1.4 No-load operation is fastest 25"/beat, normal production is 50-90"/beat, sand shooting time is 5-6 seconds, and sand mold curing time is 13-23 seconds.

1.5 Total power of the entire line: 135KW. (excluding pouring machine and air compressor)

1.6 It has intelligent fault query and fault alarm.

1.7 Casting method: bottom pouring machine (user-selected).

1.8 Mold: The outer dimensions of the lower cast iron molds are 840*840mm, and the upper cast iron molds is 835*835mm. The cast iron casting molds weight is about 850kg/pair (average value of φ50-φ120). The full line cycle has a total of 75 pairs of mold stations. At least 65 pairs of molds can be used for normal production. The practical life of the mold is 3 years. This mold for cast iron is designed as an iron mold covered with sand process. The thickness of the mold covered with sand is 3-6mm, which is suitable for casting balls of various materials. The mold plate adopts electric heating, and the mold temperature is detected by the sensor. The PLC system automatically controls the integrated sand curing time.

1.9 Process output rate: an average of about 75% or more.

We assured you that your personal information will be kept confidential. The personal data we collect is only used to process your inquiry.