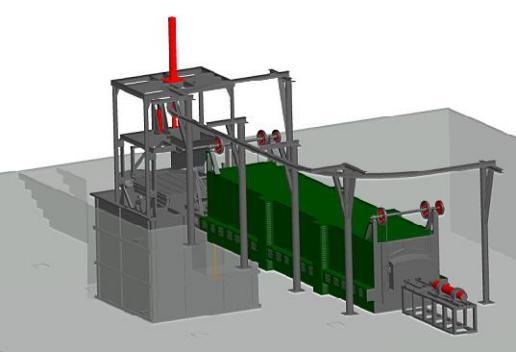

The GX series push rod type full fiber heat treatment line is a metal material heat treatment and quenching production line with induction heat treatment machine developed by our company. Our heat treatment machine uses fiber cotton and other insulation, and is controlled by PLC, intelligent temperature controller and other detection devices. Our grinding ball heat treatment line uses resistance elements to heat and automatically heat and insulate metal material products, and oil-cooling quenching treatment to change the metallographic structure of the product, improve the hardness of the product, and improve the comprehensive physical properties of the product.

1. Model specification: GX--LX-450 fiber fully automatic heat treatment production line

2. Main technical parameters:

Overall dimensions: 21x5x4 (unit: m)

Furnace body dimensions: 13.72x2.1x1.9 (unit: m)

Oil pool dimensions: 2.9mx2.6mx2.5m

Rated power: 450kw

Heating temperature zone: 4 zones

Quenching frame dimensions: 700x650x370mm

Number of quenching frames: 24

Quenching frame material: NI7N

Guide rail material: Cr24Ni7Si2

The heating element uses high temperature resistance wire, made of Ocr27Al7m2

Rated temperature: 1100℃

Working temperature: 1000℃

Frequency: 50Hz

Rated voltage: 380V

Connection method: YYYY

Furnace outer wall temperature: ≤45℃

Furnace temperature uniformity: ≤± 5℃

Temperature control accuracy: ±5℃

Furnace door lifting: automatic

Empty furnace heating time: ≤2.5h

Maximum productivity: 1.5T/h (35T/day)

1. Model specification: GX--LX-280 fiber fully automatic heat treatment production line

2. Main technical parameters:

Overall dimensions: 20x5x4 (unit: m)

Furnace body dimensions: 12.0x2.1x1.9 (unit: m)

Rated power: 280kw

Heating temperature zone: 3 zones

Tempering frame dimensions: 700x650x420mm

Number of tempering frames: 20

Tempering frame material: chromium manganese nitrogen

Guide rail material: chromium manganese nitrogen

The heating element uses high-temperature resistance wire, made of Ocr21A16nb

Rated temperature: 600℃

Frequency: 50Hz

Rated voltage: 380V

Connection method: YYYY

Outer wall temperature of furnace: ≤45℃

Temperature uniformity of furnace: ≤± 5℃

Temperature control accuracy: ±5℃

Door lifting: automatic

Empty furnace heating time: ≤2.5h

Recording method: equipped with intelligent digital display instrument and recorder bidirectional control, and also has over-temperature alarm function.

The GX series heat treatment line is a production system in an entire grinding ball production line for metal materials developed by our company. Our grinding ball heat treatment line employs fiber cotton and other insulating materials, and is managed by a PLC, an intelligent temperature controller, and various detection devices. The system uses resistance element heating to enable automatic heating, insulation, and oil cooling quenching of metal products. This process alters the metallographic structure of the products, enhancing their overall physical properties, including hardness.

We assured you that your personal information will be kept confidential. The personal data we collect is only used to process your inquiry.