Nov 08, 2024

In mineral processing, grinding media such as SAG mill grinding balls and ball mill steel balls are essential for breaking down and grinding minerals. Although they both serve similar fundamental purposes, there are significant distinctions in their specific applications, materials, and performance requirements. In this guide, we delve into the differences and connections between SAG mill balls and ball mill steel balls, helping users make informed decisions based on their unique mineral processing needs.

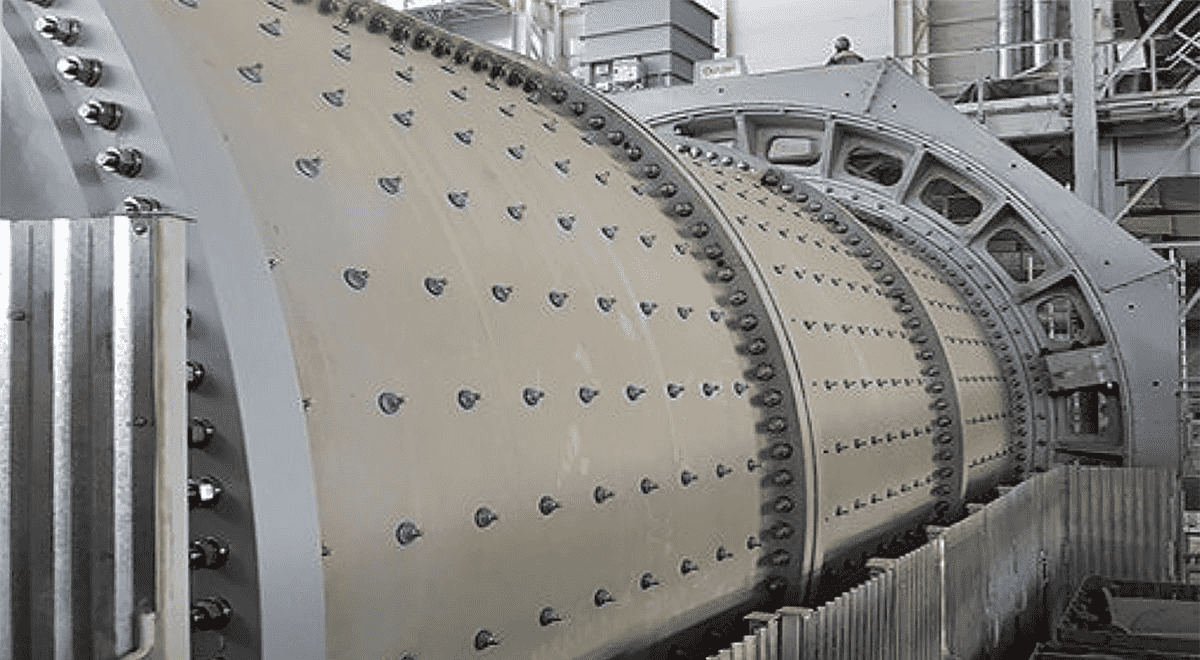

SAG Mill Balls are primarily used in SAG mills, which combine grinding and crushing. These mills process larger ore chunks, requiring SAG mill grinding media that can withstand high impacts.

Ball Mill Steel Balls are designed for use in ball mills, which focus on fine grinding of smaller particles. The gentler environment in ball mills allows these steel balls for ball mill to work effectively for fine grinding rather than for breaking down large ore chunks.

SAG mill grinding balls are typically larger and heavier than ball mill steel balls. This added mass enables them to crush and grind larger rocks and ore fragments effectively.

Ball Mill Steel Balls are smaller and lighter, which makes them ideal for refining materials to finer particles, as their smaller size allows for more precise, delicate grinding.

SAG Mill Balls serve dual purposes—both grinding and ore crushing. To endure high-stress environments in SAG mills, they are made with high impact toughness and wear resistance.

Ball Mill Steel Balls focus on grinding materials to finer consistencies, with an emphasis on hardness and durability to withstand prolonged grinding use.

SAG Mill Balls are usually crafted from high-carbon steel or alloy steel, providing the necessary impact and abrasion resistance for intense crushing applications.

Ball Mill Steel Balls are generally made of medium or high-carbon steel and occasionally alloy steel, tailored for durability in continuous grinding processes.

SAG Mill Balls are subjected to demanding conditions, exposed to significant impact and abrasion in SAG mills.

Ball Mill Steel Balls face a less intense environment, focused mainly on grinding wear without frequent high-impact forces.

Essential Role in Mineral Processing. Both SAG mill balls and ball mill steel balls play vital roles as grinding media, enabling the breakdown of ore and enhancing mineral liberation for further processing.

High Standards in Material Selection. Both types of balls require high hardness and wear resistance, and high-carbon steel and alloy steel are commonly chosen materials for their ability to endure abrasion and extend the lifespan of the grinding media.

Similar Manufacturing Processes. The production of SAG mill balls and ball mill steel balls typically involves casting, forging, and heat treatment. These steps ensure the necessary hardness, toughness, and wear resistance for grinding performance.

Durability and Longevity. Durability is essential for both types of balls, as a long lifespan reduces the need for frequent replacements, thereby maximizing production efficiency and minimizing downtime.

Understanding the distinctions and connections between SAG mill balls and ball mill steel balls is crucial in selecting the most suitable ball mill balls for sale when you buy grinding media for each specific application. Both types are engineered to meet the unique demands of SAG and ball mills, respectively, and choosing the correct media can improve mineral processing efficiency and lower operational costs.

SAG mill balls and ball mill steel balls have distinct roles in mineral processing, tailored by the needs of their specific milling environments. While sharing some fundamental characteristics and similar manufacturing techniques, their differences in size, weight, functionality, and material composition enable them to fulfill their roles effectively. By selecting the appropriate media, operators can optimize efficiency and productivity, creating a more cost-effective and streamlined mineral processing operation.

We assured you that your personal information will be kept confidential. The personal data we collect is only used to process your inquiry.